Frequently Asked Questions

Read our answers to common questions

Why use stainless steel?

Stainless steel is easily welded, has an attractive finish and is low maintenance. There is no doubt that stainless steels are one of the most sustainable of materials available today. They are manufactured with high recycled content (above 80% in many cases), have low GHG emissions and routinely offer the lowest life-cycle costs of any available materials we have at our disposal. Stainless steels, when correctly specified, will provide service lives of greater than 100 years with minimal or zero maintenance. They have amazing hygienic properties, supreme corrosion resistance which when combined with their strength characteristics provide an opportunity for significant material light-weighting which few other materials can match. They are also incredibly simple to recycle at their end-of-life and do not carry the need for extensive processing to make them ‘recycling ready’.

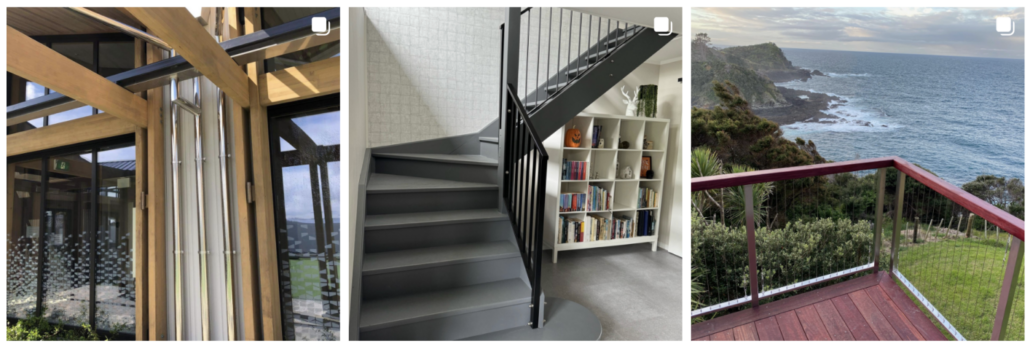

Can I use horizontal stainless steel wire balustrade infills?

The short answer is no. The NZ Building Code (Section F4 – Safety from Falling) precludes balustrades which can be considered climbable by children under 6. A popular alternative and code compliant choice is parallel vertical wire infill or a zigzag pattern wire infill.

What is the standard height for a balustrade?

For residential buildings the minimum height for balustrades and barriers for stairs, ramps and landings is 900mm. For balconies and decks this increases to 1000mm.

Why is there a top capping to a frameless glass balustrade?

All frameless glass balustrades are required to have an interlinking top rail to prevent the collapse in the event of breakage of panes of glass. This is in accordance with Acceptable Solution B1/AS1, Amendment 13. This ensures that should any pane of glass fail, the structural integrity of the balustrade remains intact.

Which grade of stainless steel do you use?

We fabricate both 304 and 316 grades of stainless steel. Grade 316 is particularly suited to New Zealand’s largely coastal environment and is used in all exterior applications. Grade 304 stainless works well for interior items.

What finishes are available?

The end product can be a satin (brushed finish, 320 grit) or polished finish (mirror finish 600 grit). We can also electropolish for greater corrosion resistance. Powder coating stainless steel is also an option for a visual aesthetic, particularly if you wish to colour match your joinery.

How do I care for stainless steel handrails and balustrades?

Due to the durability and corrosion resistance of stainless steel, there is very little maintenance required, making it a popular choice. For a maintenance and care manual, click here (LINK)

What is a PS1?

This site-specific Producer Statement ensures our balustrade is compatible with your building structure. It gives evidence that the design and works comply with the Building Code. We can provide these where necessary.

What is a PS3?

This document verifies that we have followed the PS1 design and installed the balustrade in accordance with the Building Code. Stainless Works is registered with Auckland City Council as an approved expert for issuing PS3’s for our own installations.

What health and safety precautions do you take?

All our staff are site safe accredited and we are fully versed in current building codes, rules and regulations. We provide SSSP’s and TA’s where required.